OUR NANOPARTICLE MANUFACTURING SYSTEMS

TAMARA

The only plug and play nanoparticle formulation system with microfluidics that covers all development stages

Using advanced microfluidic technology, TAMARA ensures precise control of size, PDI, and EE% for RNA-LNP, liposomes, SLN, PLGA nanoparticles, and more.

Its user-friendly design supports formulation from µL to 10+ mL, making TAMARA ideal for every stage of your development, from screening to in-vivo.

Streamline your RNA-LNP and nanomedicine research with TAMARA.

They trust us

We’ve set up TAMARA and performed our first mock run. I gotta say, I’ve operated everything from flow cytometers to NGS instruments of varying degrees of quality and efficiency, and I’m absolutely blown away by how user friendly, efficient and straight to the point this system is!

Easy and quick

Setup, run and collect your nanoparticles in less than 2 minutes, even as a begginer

Size, PDI and EE% control

Get access to the most advanced microfluidic technology for the optimal control of your nanoparticle characteristics including size, PDI, encapsulation efficiency...

Chips cleaning

Be sustainable and save money by cleaning your chips between runs, allowing you to reuse them!

All your development with one platform

Use the same system to streamline your development by formulating identical nanoparticle from your discovery stage (200µL) to your in vivo testings (up to 10mL/batch)

Discover TAMARA

The most accessible nanoparticle synthesis platform

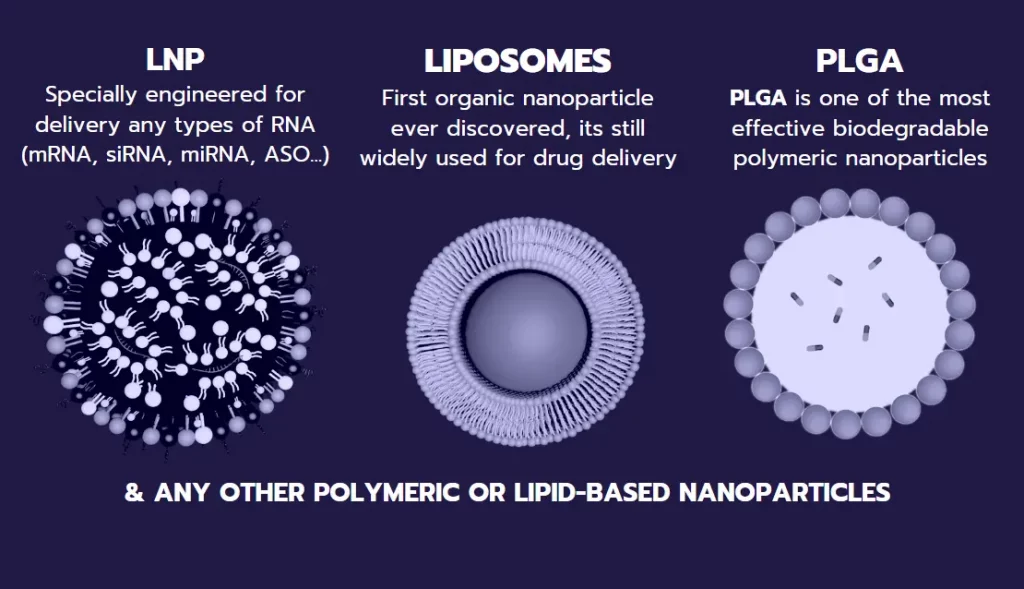

Lipid Nanoparticle/LNP

Utilize the TAMARA system to formulate customized lipid nanoparticles (LNP) for the effective delivery of mRNA, siRNA, tRNA, DNA, saRNA, or ASO to target cells or organs.

Liposomes & SLN

With nanoprecipitation technology, the TAMARA system can synthesize most types of lipid-based nanoparticles, including liposomes and SLNs.

Polymeric Nanoparticles

The flexibility of the TAMARA platform also allows for the synthesis of a wide range of polymeric nanoparticles, such as PLGA, polystyrene, and hybrid nanoparticles.

And more nanoparticles

Beyond polymer and lipid-based nanoparticles, the TAMARA platform is versatile enough to produce protein nanoparticles, nanoemulsions, and more.

FEATURES

Nanoparticle formulation with microfluidic has never been this easy

Intuitive operation: Synthesize your nanoparticle in less than 2 minutes with the TAMARA platform. Simply set your formulation parameters, load your sample, and press on run!

You can also save your synthesis parameters for your next runs

Chip & reservoir cleaning: Easily clean your chip and reservoirs!*

*Note: The guaranteed outcome is for the first run only. Chip's reusability depends on formulation and target volume.

A single platform for all your development

Scalability: Utilize the same platform for all your screening, in-vitro, and in-vivo tests with our nanoparticle formulation system, covering volumes from 0.2 to 10 mL. *

*Accuracy & repeatability are ensured in the 0.5 to 5 mL range.

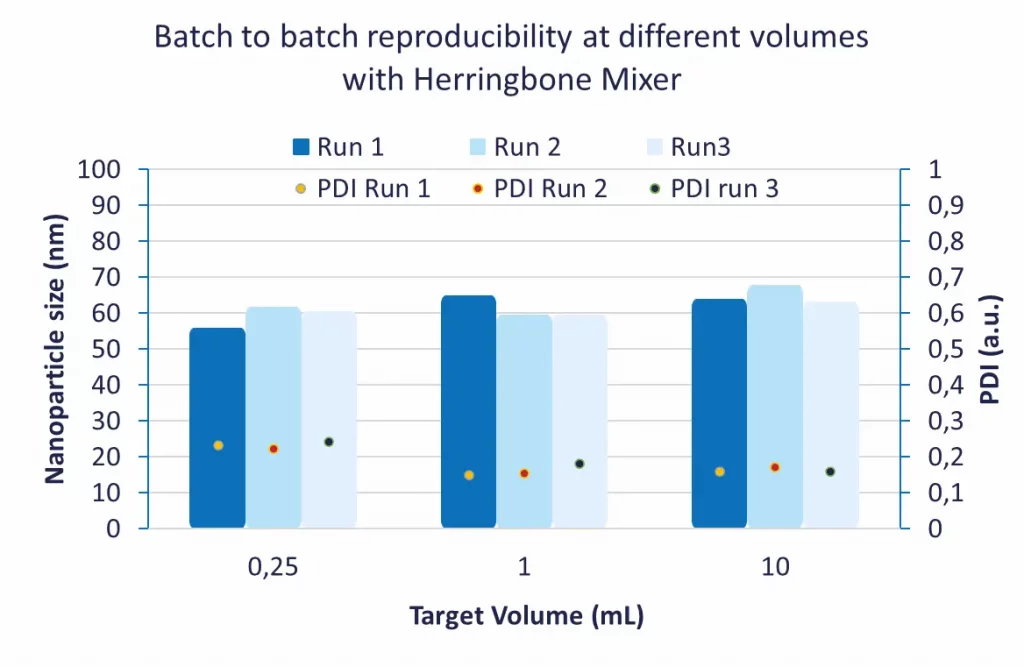

Batch-to-Batch Consistency: Achieve consistent nanoparticle characteristics with every batch, ensuring optimal repeatability for your experiments.

Maximize Reagent Efficiency: Our near-zero loss system maximizes reagent consumption, reducing waste and optimizing your resources.

The best of microfluidics, for the best performances

Optimal size control: Effortlessly reach your target nanoparticle size by tuning your synthesis parameters using our user friendly features.

Best Polydispersity Idex (PDI): Get access to the most advanced microfluidics technology to achieve the most homogenous nanoparticle populations.

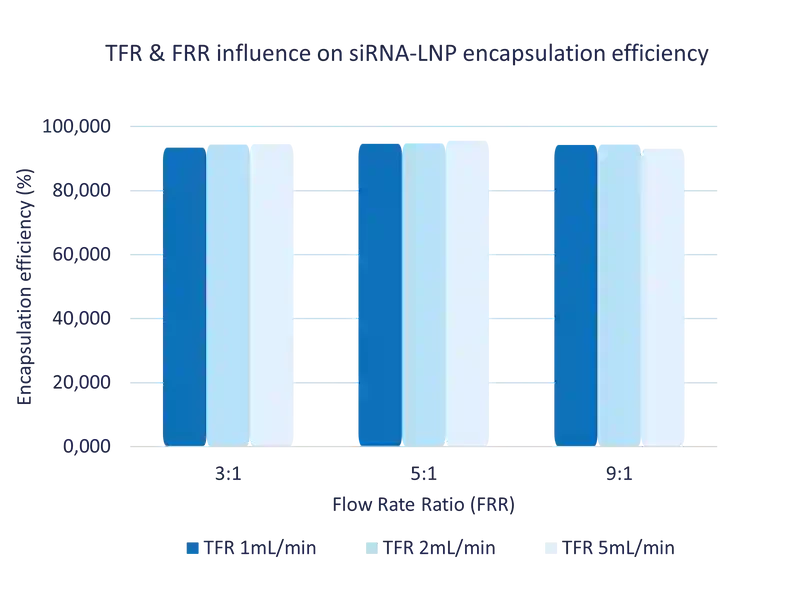

Maximized encapsulation efficiency

Achieve the highest EE%: Employing state-of-the-art microfluidic technology, the TAMARA platform permits to reach encapsulation efficiency as high as 97% with RNA-LNP!

Payload flexibility: What is true for RNA-LNP (siRNA, mRNA, miRNA...) is also true for a wide majority of payloads including DNA, CRISPR/CAS9, small molecules, peptides, drugs...

Wide range of nanoparticle types

One platform for all: TAMARA allows for the synthesis of most polymeric and lipid-based nanoparticles (RNA-LNP, liposome, PLGA…) within one single platform.

Solvent compatibility: Use most polar solvents (Ethanol, Methanol...) for the synthesis of your nanoparticles.

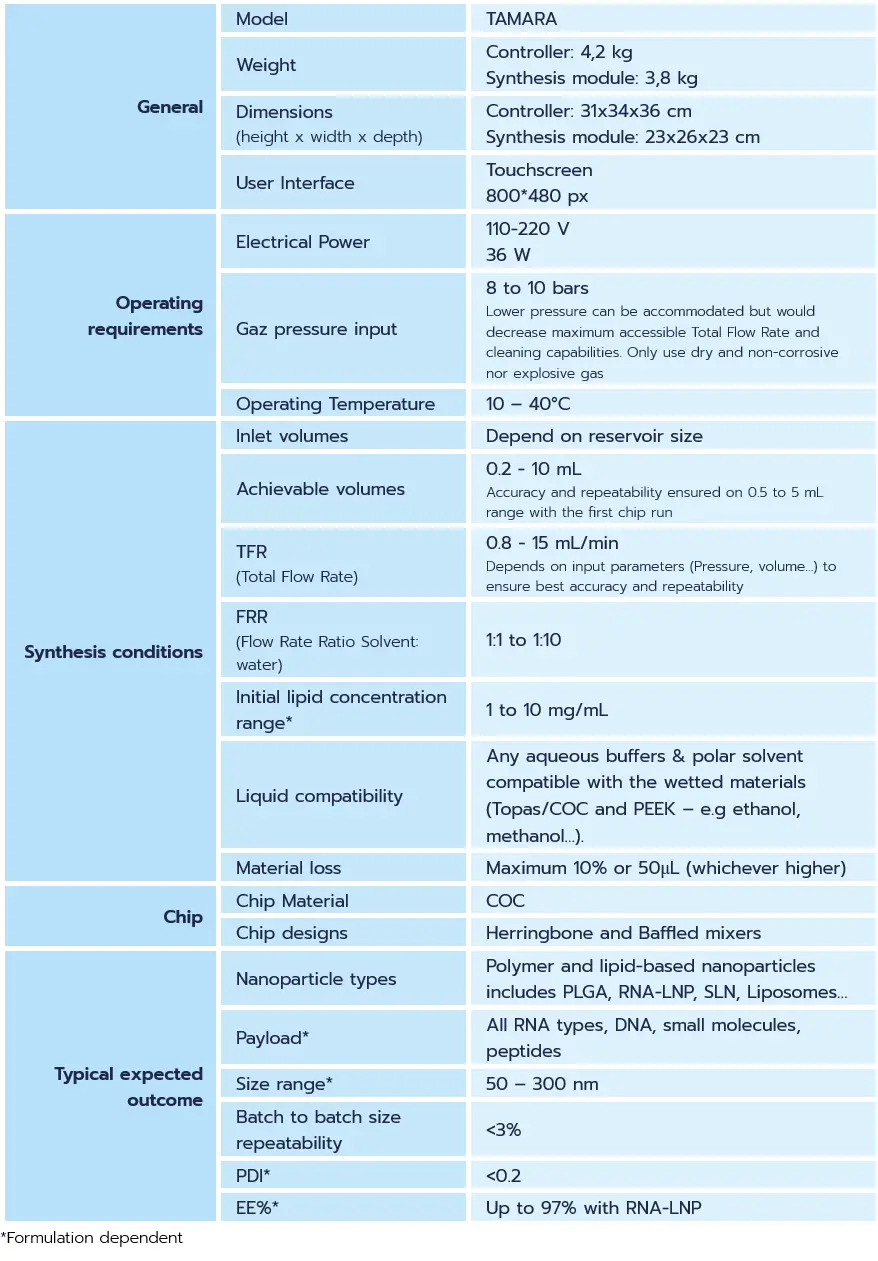

TAMARA Specifications

TAMARA specifications

Related Documentation

TAMARA User Manual: Download

TAMARA applicaiton note: Liposomes synthesis and size characterization with high precision DLS

I am looking to test if my RNA strand can be encapsulated into LNP

Perfect for newcomers to the nanoparticle and/or microfluidic field, the TAMARA platform will allow you to easily and quickly synthesize your nanoparticles, even without prior experience

I want to optimize my screening process

The TAMARA platform allows for very low volume synthesis (0.2 mL) and cleaning in less than 2 minutes, allowing you to synthesize and test 10s of samples a day.

I am looking to improve the quality and reproducibility of my nanoparticles

By using the same system from screening (down to 0.2µL) to preclinical tests (10mL batches), you optimize your chances of success as you are sure to maintain your nanoparticle characteristics identical all along your development process.

We are positively impressed with the Inside Therapeutics solutions. They provided us with detailed instructions to set up the equipment, which made the system quick and easy to start. We found the equipment very user-friendly and the entire experience was highly reproducible. We were able to consistently produce lipid nanoparticles with encapsulated siRNA for drug delivery applications, with precise control of the physicochemical characteristics of the nanoparticles